1. Introduction

PVC fabric is a synthetic material made primarily from polyvinyl chloride (PVC). It occupies an important position in the modern materials field and has a unique development history.

Historically, PVC fabric first appeared as a plastic-coated fabric. Initially, PVC was applied as a coating on base materials. However, with continuous technological advancements, it has evolved into a modern synthetic material with various functions, greatly expanding its range of applications.

2. Manufacturing Process of PVC Fabric

- Raw Materials: The basic components of PVC fabric include polyvinyl chloride resin, which is the core material; plasticizers, which increase the fabric’s flexibility; and stabilizers, which ensure the material’s stability during processing and usage.

- Production Techniques:

- Coating Technology: PVC resin and other components are mixed to form a coating, which is applied evenly to the surface of the base material, creating a PVC fabric layer with specific properties. Common examples include single-sided and double-sided coated fabrics.

- Heat Pressing Technology: High temperature and pressure are used to shape the PVC material, allowing the creation of PVC fabric products with uniform texture and well-defined shapes.

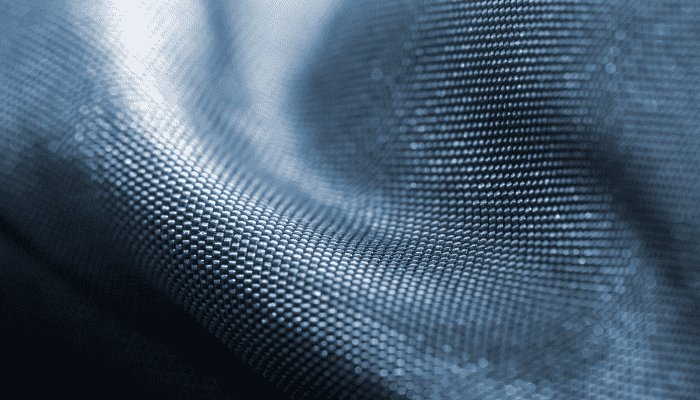

- Weaving Technology: PVC fibers or PVC composite fibers are woven to create woven PVC fabric, which has unique textures and properties.

- Types: Based on different manufacturing processes, there are single-sided coated PVC fabrics, which have PVC coating on one side, double-sided coated PVC fabrics, where both sides have corresponding properties, and woven PVC fabrics, each suitable for different applications.

3. Properties of PVC Fabric

- Durability: PVC fabric is resistant to abrasion and tearing, maintaining good integrity over time and withstanding a certain degree of external pulling and friction.

- Water Resistance: PVC fabric has excellent waterproof properties, making it ideal for outdoor environments, such as camping tents and boat covers, effectively preventing rainwater penetration.

- UV Resistance: PVC fabric can resist sun exposure and environmental changes, reducing aging and fading caused by UV radiation, and thereby extending its service life.

- Easy to Clean: Its smooth surface prevents stains from adhering, and it can be easily cleaned with a simple wipe or wash, making it convenient for daily maintenance.

- Flame Retardancy: Some PVC fabrics have flame-retardant properties, making them suitable for industries with high fire safety requirements, such as industrial protective gear.

4. Applications of PVC Fabric

- Home Decor: PVC fabric is commonly used to make waterproof tablecloths, preventing water stains and dirt; curtains that provide light-blocking, decorative, and waterproof functions; and sofa covers that protect sofas while being both aesthetically pleasing and easy to clean.

- Outdoor and Sports: Tents and sunshades rely on PVC fabric’s water resistance and UV resistance to provide shelter for outdoor activities; swimming pool covers effectively prevent debris from entering the pool and help maintain water temperature.

- Industrial Use: Protective clothing and workwear provide safety for workers, while conveyor belts use PVC fabric for its durability to transport materials.

- Automotive Industry: PVC fabric is used for seat covers and interior decorations in cars, adding aesthetic appeal while being easy to clean.

- Medical Field: PVC fabric is used to make medical equipment covers and protective pads, offering protection while being easy to clean and disinfect.

5. Advantages and Disadvantages of PVC Fabric

- Advantages:

- Strong Waterproofing: Ideal for outdoor products, keeping items dry in humid environments.

- Easy to Clean and Maintain: Saves time and effort.

- Durable and Wear-Resistant: It can be used for a long time without significant damage, offering good value for money.

- Disadvantages:

- Environmental Impact: PVC is not easily biodegradable in the natural environment and may persist for a long time after disposal.

- Potential Harmful Substances: It may contain harmful substances like plasticizers, although environmentally friendly PVC materials have been developed in recent years.

- Heavier Than Natural Fibers: In some applications where weight is a concern, PVC fabric may be less ideal.

6. Environmental Issues and Sustainability of PVC Fabric

- Environmental Challenges: PVC fabric production may generate pollutants, and its degradation in the natural environment is difficult, potentially posing risks to soil and water sources.

- Recycling and Alternatives: Innovative eco-friendly materials and recycling technologies are being developed. For example, improved recycling processes are increasing the recycling rates of PVC fabric, while alternatives such as plasticizer-free PVC and bio-based PVC are being introduced to reduce environmental impact.

7. Future Development Trends

- Advances in Eco-friendly Technology: For example, using plasticizer-free PVC substitutes can reduce harmful substances, and the development of bio-based PVC makes it more sustainable by improving the sourcing of the material.

- Innovative Applications: The application of PVC fabric in emerging industries holds great potential. For example, in the field of smart textiles, it may combine with sensors to achieve additional functions, while in wearable devices, it could play a unique role, further expanding its applications.

8. Conclusion

PVC fabric, with its diverse properties, has demonstrated strong versatility and has wide applications across various industries. However, its environmental issues cannot be ignored. Looking ahead, with advancements in eco-friendly technology and the expansion of innovative applications, PVC fabric is expected to play a significant role in more fields while minimizing environmental impact, achieving the goal of sustainable development.