Screen printing, as an important printing technique, is widely used in the field of fabric printing. The following will introduce its related points in detail for you.

I. Introduction to Screen Printing

Simply put, screen printing is a process of transferring ink onto fabrics through a screen plate. It has many advantages. It can achieve high-quality printing on various fabrics, is highly suitable for mass production, and the printed patterns are bright in color and long-lasting.

II. Material Preparation

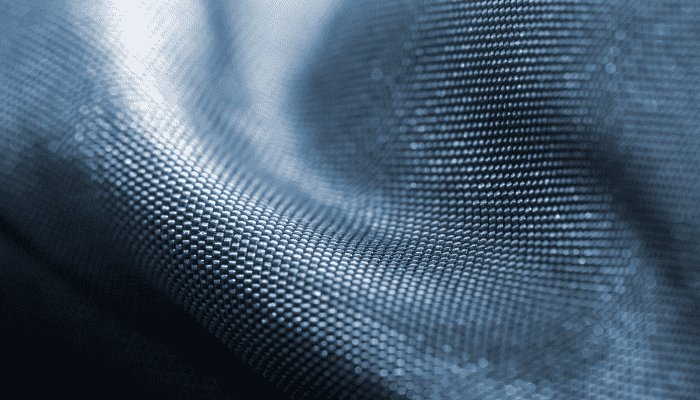

– Selecting Fabrics: Different fabrics such as cotton, polyester fiber, nylon, etc. have an impact on the printing effect. Appropriate fabrics should be selected for printing according to specific requirements.

– Types of Ink: Common ones include water-based ink, oil-based ink, solvent-based ink, etc. Different inks are suitable for different types of fabrics.

– Screen (Screen Plate): There are various types of screens. The mesh count should be reasonably selected to pick out a screen suitable for fabric printing.

III. Steps of Making Screen Plates

– Design and Pattern Preparation: Design files need to be prepared using design software to ensure that the resolution and color mode of the patterns are suitable for printing.

– Making Screen Plates: The design patterns can be transferred onto the screen plates by means of photosensitive processes or direct hand-drawing, etc.

– Exposure and Plate Washing: If a photosensitive screen plate is used, exposure and plate washing operations are required to remove the unhardened part of the coating and retain the patterns.

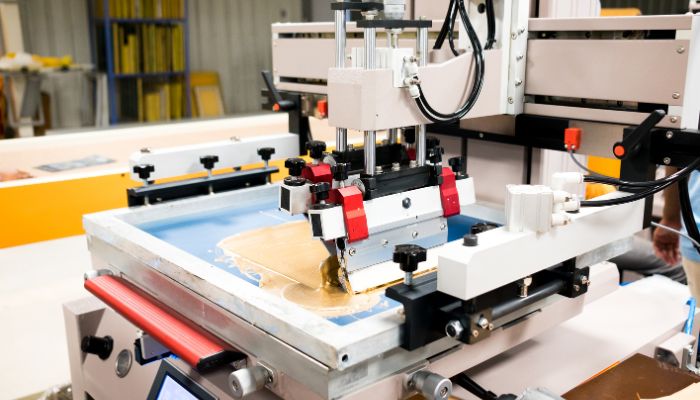

IV. Equipment and Tools

– Screen Printing Machines: There are manual and automatic ones. The machines should be set up properly according to the type of fabric and printing requirements.

– Squeegees: The usage techniques of squeegees should be mastered, and appropriate hardness and width should be selected as they will affect the printing quality.

– Other Tools: Tools such as screen plate frames, ink trays, heat treatment equipment, etc. also have their respective usage methods.

V. Operating Steps of Screen Printing

– Preparation Work: Clean the surface of the fabric to make it dust-free and flat. Meanwhile, set up the screen printing machine and the screen plate.

– Applying Ink: Place an appropriate amount of suitable ink above the screen plate.

– Printing Process: Use a squeegee to evenly spread the ink above the screen plate, allowing the ink to be printed onto the fabric through the screen plate.

– Repeated Printing: In multi-color printing, each layer should be dried before the next layer is printed.

VI. Drying and Curing

– Drying Methods: Different inks require different drying methods, such as air drying or accelerated drying with the help of heating equipment.

– Curing Process: Many inks need to be cured by heat treatment so that the printed patterns will be more durable.

VII. Quality Inspection and Post-Processing

– Inspecting Pattern Quality: Check the clarity, color uniformity, and durability of the printed patterns to avoid problems such as missing prints and double images.

– Post-Processing: If necessary, make manual repairs or corrections to details to ensure that the printing quality of each fabric meets the standard.

VIII. Cleaning and Maintenance

– Cleaning Screen Plates and Tools: Learn to clean screen plates, squeegees, and other tools to prevent the ink from drying up and affecting the next printing.

– Equipment Maintenance: Regularly inspect the conditions of screen printing machines and other equipment to ensure their long-term efficient operation.

IX. Common Problems and Solutions

– Blurred or Unclear Patterns: This may be caused by factors such as the ink being too thin, the mesh count of the screen plate being inappropriate, or the squeegee being used improperly. Adjustments should be made accordingly.

– Ink Penetration or Missing Prints: This can be avoided by adjusting the printing pressure, the tension of the screen plate, etc.

– Uneven Colors: The color uniformity can be ensured by adjusting the mixing ratio of the inks and controlling the pressure.

X. Creative Applications

– Personalized Design: Creative printing can be carried out on clothing, bags, home textiles, etc. to produce personalized and customized products.

– Environmental Protection Printing: By adopting environmentally friendly inks and production methods, screen printing can meet the requirements of sustainable development.

XI. Market Prospects

Screen printing is widely used in fields such as fashion, home textiles, and sportswear in the textile industry. With the development of technology, its precision, environmental friendliness, and versatility will continue to improve.

In conclusion, screen printing has obvious advantages in fabric applications. It is efficient, durable, and suitable for mass production, and can meet various creative designs. Everyone can choose the appropriate screen printing method according to their own needs to create high-quality, personalized fabric products.